Designing Modularity for Mission Profiles

I woke up way before dawn, as usual, and had a question for Ai…what if engine modularity wasn’t about convenience—but clarity? What if each module carried the DNA of a broader purpose?

Why It Matters

In aviation, misalignment between mission and machinery kills efficiency, cost, and often ambition. Founders and builders try to force legacy systems into new use cases—and break things. At UnobtaniumX.com, we do the opposite.

UnobtaniumX.com exists to deliver elegant, off-path solutions for those who demand leverage and clarity. That starts with modular design—built not around horsepower numbers, but mission archetypes.

1. Mission-Driven Modularity: The Big Shift

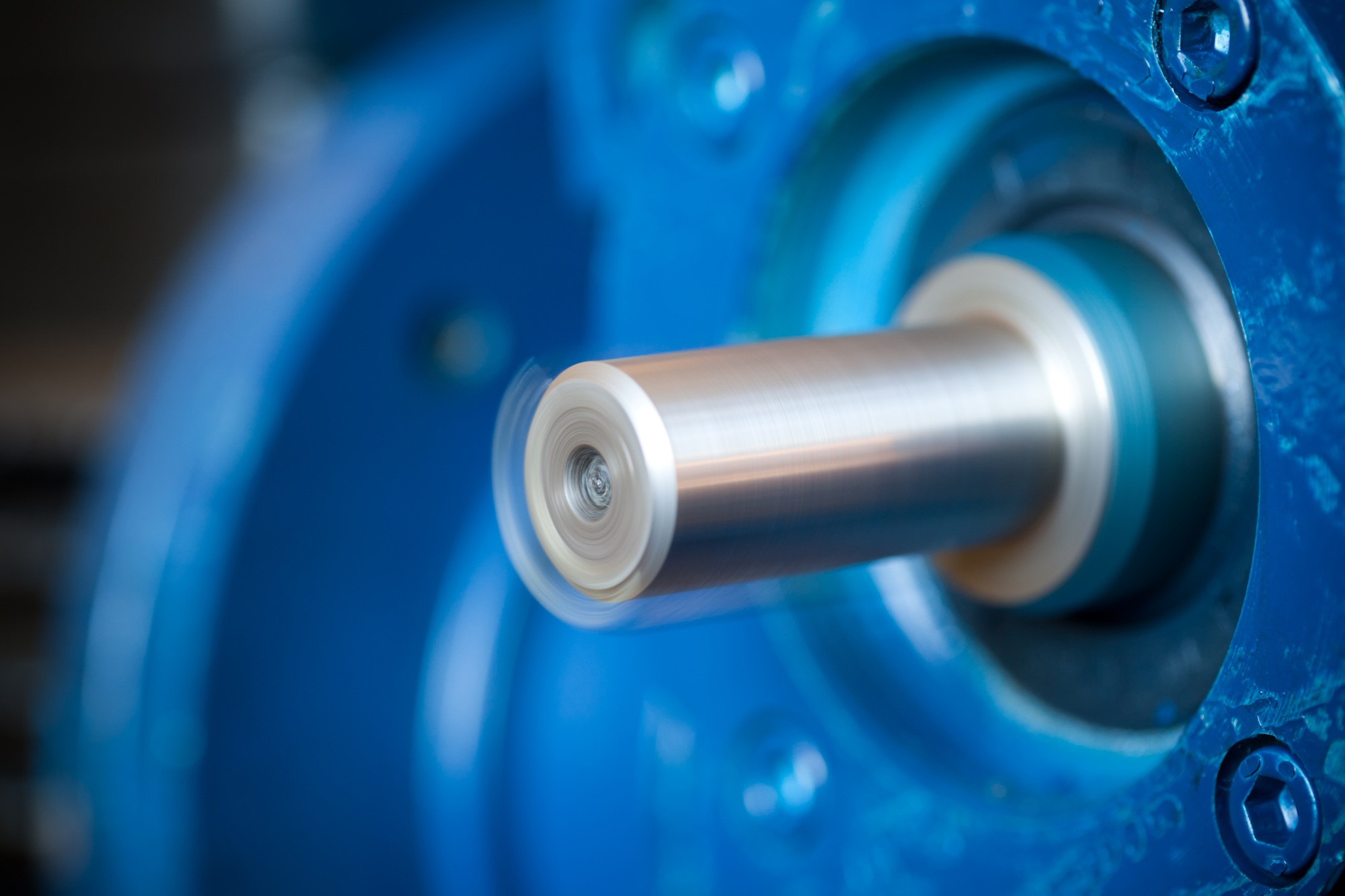

Modular engine families often start with mechanical ease or maintenance logic. We start elsewhere: intent. Every aircraft mission—STOL bushcraft, regional LSA, tactical evac—demands different torque bands, cooling loads, and burn profiles.

Instead of designing separate engines, we designed one platform to scale up or down based on:

- Flight duration and climb requirements

- Fuel redundancy needs

- Power vs. weight tradeoffs

- Thermal behavior under load

The result? 100HP, 200HP, and 300HP configurations that share core DNA but specialize for performance.

2. From Single Mission to Multi-Class Power

A modular system allows:

- Experimental aircraft builders to prototype once, then upscale power if needed.

- Pilots to plan mixed-mission use without over-engineering.

- Maintenance crews to service engines with shared parts across fleets.

This isn’t just flexible—it’s economic. One ecosystem, many aircraft. One learning curve, many missions.

3. Why Modularity Beats Customization

Customization feels empowering but leads to decision fatigue, fragmented parts, and inconsistent diagnostics. Modularity simplifies options without neutering control. It’s clarity, not compromise.

- Mistake: Building a unique engine for every dream

- Pro Tip: Build one dream platform that powers many missions

4. Performance Isn’t Lost—It’s Leveled

Some assume modularity means dull, underperforming engines. Not here. Each X123 configuration is:

- Optimized for its class envelope

- Tuned with redundancy in mind

- Delivered with diagnostic logic baked in

You don’t lose power—you earn reliability.

Mistakes & Insights

- Mistake: Equating modularity with lowest-common-denominator engines

- Insight: Modularity reveals elegance when mission clarity leads design

Next Steps CTA

One engine platform. Three mission-ready configurations. Built with obsession. Learn more at UnobtaniumX.com.

FAQ

What is mission-driven modularity?

Designing modular components around real-world aircraft missions, not marketing categories.

Can I start with 100HP and move up later?

Yes. The X123 Platform is built for scalable upgrades without rebuilding from scratch.

What makes modularity better than custom builds?

Lower cost, fewer parts, and consistent diagnostics across configurations.

Will I sacrifice performance using a modular engine?

No. Each X123 tier is tuned to outperform in its class with reliability and smart systems.

Who benefits most from this design?

Aircraft designers, funders, and pilots building for diverse flight missions or evolving needs.

Can one airframe support all three versions?

Depending on weight and balance, yes. That’s part of the modular philosophy.

Is this available now?

The design is complete. Build partners and funders welcome via UnobtaniumX.com/contact.

Written by UnobtaniumX.com Editorial Team. Learn how we craft insights with obsessive clarity at UnobtaniumX.com/about.